Circular economy: definition

The circular economy is the most advanced production and consumption model, consistent and aligned with the concept of sustainable development.

It is strongly supported by European Union regulations through initiatives such as the Circular Economy Action Plan, that sets political directions, regulations, and incentives to lead the single market through this type of transition.

Alongside this, the Ellen MacArthur Foundation is a key entity working to promote the circular economy, engaging with economic and political decision-makers to implement innovative and sustainable solutions. Together, these efforts show an increasing commitment to a future that is both sustainable and resilient.

“Circular economy is a generic term for an economy designed to be self-renewing. In a circular economy, there are two types of material flows: biological flows, which stand to be returned to the biosphere, and technical flows, intended to be enhanced without entering the biosphere». Ellen MacArthur Foundation

The origin of the concept of Circular Economy

The implementation of the circular economy concept within modern economic systems and industrial processes began to take shape in the 1970s.

One of the earliest references to the idea of a circular materials circuit is found in the work of Kenneth E. Boulding, who published the article “The Economics of the Coming Spaceship Earth” in 1966.

Building on this foundation, Walter Stahel and Genevieve Reday delved deeper into the idea in 1976 with their report for the European Commission titled “The Potential for Substituting Manpower for Energy.” Their research highlighted the circular economy’s capacity to drive job creation, save resources, and reduce waste.

The Ellen MacArthur Foundation is the first international no-profit organization, established in 2010, with the aim of “Support creative people and institutions committed to building a more just, verdant, and peaceful world “. The foundation supports companies and educational institutions in the transition to more sustainable practices.

Its mission is to accelerate the transition toward an economic system that replaces the linear “take-make-waste” model with a “cradle-to-cradle” approach, considering the entire life cycle of products.

Linear to circular model

The linear economic model, prevalent throughout the industrial era, assumes that resources are plentiful and easily accessible, resulting in inefficient use and the production of substantial waste. In this model, we mine materials from the Earth, create products and finally discard them, following a linear process: “extract, produce, use and waste”.

Conversely, the circular economy seeks to drive out waste through smart design and seamless reuse of materials, promoting sustainability and efficiency.

Why the circular economy is urgent

The circular economy brings in practices that prolong the life cycle of products, cutting down on waste and reintegrating materials into the production cycle to create fresh value.

Materials never become waste, but remain in circulation through maintenance, reuse, reconditioning, remanufacturing, recycling and composting, and nature is regenerated. The circular economy addresses global challenges such as climate change, biodiversity loss, waste and pollution by separating economic activity from the consumption of finite resources. It has three basic goals: eliminate waste and pollution; keep products and materials in circulation, preserving their value; regenerate nature.

Supported by the transition to renewable energies and materials, the circular economy is a resilient system that benefits businesses, people and the environment.

Raw materials

The issue of raw materials is the focus of the circular economy, set up to prevent over-exploitation of such materials. The latter are not an endless or renewable resource.

Nevertheless, according to the recent OECD report, titled The Global Material Resources Outlook to 2060, the world’s consumption of raw materials will reach 167 billion tons in 2060, almost double the current level, and without tangible action, the damage will be extensive.

In addition to the depletion of some raw materials, increased mining and processing of materials results in emissions of climate-changing greenhouse gases, air, water and soil pollution, destruction of ecosystems.

If the “ability of future generations to meet their own needs” is not to be endangered, the management of raw material use must be approached in a better way. Shifting to a circular economy is among the strategies to achieve this goal, promoting a lifecycle where materials are kept in use for as long as possible and the use of new resources can be minimized through recycling.

Industrial transition in the circular economy

The circular economy embodies a self-sustaining economic system where biological materials are reintegrated into nature and technical materials reused without environmental harm. In contrast to the conventional model, which overuses natural resources and prioritizes profit over production cost reduction. Embracing the circular economy requires a fundamental shift in production processes aimed at securing enduring sustainability.

In this context, eco-design practices steer the creation of products conceptualised for their entire life cycle, guaranteeing effortless disassembly, refurbishment, recycling or reutilisation. Modularity and adaptability play a vital role in crafting products that can adjust to alterations, extending their utility and lessening the demand for fresh resources. The adoption of renewable energy substitutes fossil fuel sources, aiding in diminishing the carbon impact of manufacturing operations.

Adopting an ecosystems approach enables the consideration of interactions among various system components, reducing adverse externalities and enhancing the ecological and social contexts. Ultimately, material recovery replaces the use of virgin raw materials with reclaimed materials, preserving their qualities and diminishing reliance on natural resources, rounding out a fundamentally renewed and responsible economic model.

Circular economy: a profitable business model

The circular economy innovatively safeguards resources and ecosystems. An approach that involves designing products to prolong their lifespan, encourage reuse, remanufacture, and eventual recycling while conserving resources like materials, energy, and time used in their creation.

To date, many companies will incur costs in transitioning to the circular economy. However, it is quite clear that in the medium and long term there are numerous benefits, including from a business perspective. For example, companies will incur lower raw material acquisition and production costs, while consumers benefit from lower prices.

The thrust of the circular economy has fostered the emergence of new business models and industrial strategies based on the circular approach, which over time are proving to be innovative and effective from a value-added perspective

“Product as a service” (Paas) is a new business model, where companies, as opposed to selling products, offer the use of those products as a service. A striking example are Car2Go, Zipcar or Link&Co, which offer cars with new rental or sharing formulas rather than selling personal vehicles; Apple and Samsung, offer leasing programs for smartphones and other electronic devices; Xerox, offers printing and document management solutions rather than selling printers.

Industrial symbiosis and remanufacturing chain, both promote circularity, the former focusing on cooperation between different enterprises for optimal resource management, the latter on reuse of materials within a specific supply chain or industry..

Upcycling is redefining entire industries, from clothing to construction.

Finally, “product lifetime extension,” in addition to being a principle of the circular economy turns out to be, counter-intuitively to hitherto followed drivers such as planned obsolescence, a new business opportunity, through maintenance, repair or improvement.

Creating value in a circular economy means leveraging innovation to develop regenerative businesses that improve their profitability and resilience, reducing costs for consumers and benefiting the environment and communities.

The R rule: the entire life cycle between raw materials and products

The Rule of 5 “R” is a fundamental concept for promoting sustainable waste management and is now part of the circular economy. Introduced in Italy in 1997 with the Ronchi Decree, the law that revolutionized waste management in Italy by transforming the concept of waste from a problem to a resource, this strategy aims to reduce the environmental impact of waste through 5 key principles: Reduce, Reuse, Recycle, Collect and Recover.

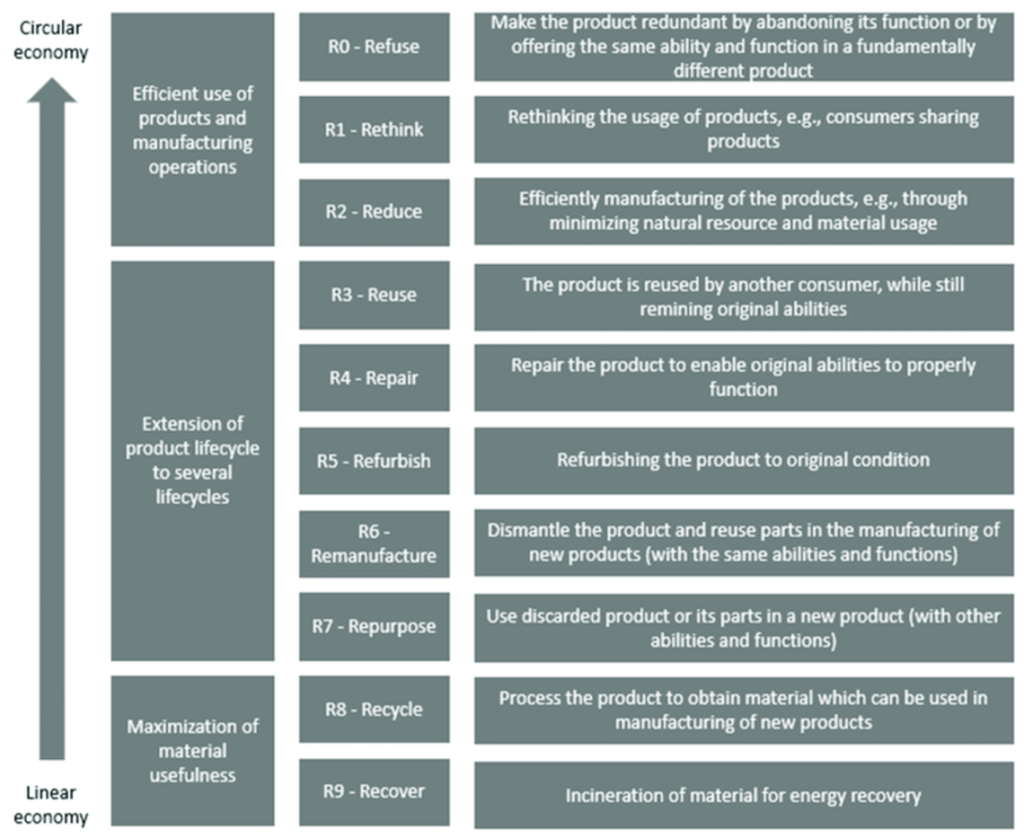

Over time, as the focus shifts towards the circular economy, additional “R” have emerged, embodying circular strategies for designing products and byproducts that businesses across various sectors can embrace.

These initiatives are now consolidated into a list of nine principles, encapsulated in “The 9R Framework on the Circular Economy,” (https://www.researchgate.net/figure/The-9R-Framework-Source-Adapted-from-Potting-et-al-2017-p5_fig1_320074659), delineated into three overarching categories:

- Use and manufacturing of smart products:

- R0 – Refuse: avoid misuse of a product, choosing multifunctional alternatives instead;

- R1 – Rethink: Boost product implementation through innovative and sustainable management, such as shared economy services;

- R2 – Reduce: Increase efficiency in production and output, minimizing the consumption of natural or new resources.

- Extension of the lifetime of the product and parts thereof:

- R3 – Re–use: Re–use a cast-off product that can still properly serve a new user;

- R4 – Repair: Fix a failed device.

- R5 – Refurbish: Upgrade an obsolete product to meet new consumer needs;

- R6 – Remanufacture: Produce a new object from the parts of an old one with the same functions;

- R7 – Repurpose: Create a new product with different functions using parts of existing products.

- Useful application of materials:

- R8 – Recycle: Process used materials into new raw goods of the same or lower quality;

- R9 – Recover: Get energy from materials through burning, generating value from otherwise useless resources.

EU circular economy policies and the role of packaging

In March 2020, the European Commission revealed an Action Plan to boost sustainability, cut down waste, and lower CO2 emissions, aligning with the Green Deal‘s target for climate neutrality by 2050.

Packaging holds a pivotal position in managing resources and waste, influencing the ecological impact across various sectors by facilitating resource consumption and waste production.

The EU has been working on a fresh regulation tailor-made for the packaging industry since November 2022 (https://www.europarl.europa.eu/news/en/press-room/20240419IPR20576/ecodesign-new-eu-rules-to-make-sustainable-products-the-norm), to enhance design, improve labeling clarity, and advocate for reuse and recycling. The proposed regulation paves the way for a shift towards the adoption of organic, biodegradable, and compostable plastics, bolstering the transition towards a circular economy.

Packaging: the definition

The core purposes of packaging are and should mainly consist of the following:

- containing: storing the product intended for the consumer;

- protection: preserving the contents from impact, external contact and contamination, preserving its quality;

- handling: facilitate the transport of the product along the distribution chain, from producer to consumer;

- presentation: enhance the value of the product by serving as a communicative tool to transfer information from the company to the consumer;

Sustainable packaging is designed to minimize environmental impact and maximize effectiveness in its functions. Addressing sustainable packaging involves delving into a wide range of sectors, spanning from design to logistics, and recycling, essentially covering the entire lifecycle of packaging.

Eco-design

Sustainable packaging stems from eco-design, the design of the packaging itself, which takes into account environmental, functional, and business needs and must imagine the best solution. It is worth recalling that, in general terms, eco-design is not only about creating “green” products, rather it holistically considers all components of sustainability, thus including people (human rights) and the economy, fostering a long-term vision through innovation and raising environmental awareness.

In this article, we focus on eco-design primarily through an environmental lens, considering the product’s circular footprint.

This includes energy efficiency, the use of recyclable or biodegradable materials, waste reduction, and environmental impact mitigation during production and distribution. Additionally, eco-design encourages sustainable practices across the value chain, engaging suppliers, producers, and consumers.

Eco-design taps into innovation to come up with creative and sustainable solutions. This entails not only cutting down on environmental impact but also crafting products that are ergonomic, aesthetically pleasing, and functional, catering to users’ needs without depleting natural resources.

Food packaging

In the food sector, the concept of sustainable packaging must harmonize environmental health with human well-being.

Packaging in direct contact with food, from production through distribution to final delivery to the customer, needs to safeguard wholesome and intact food, preserving its sensory attributes. It should shield the food from external substances, alterations, contamination, and adulteration. I In a more conscious and evolved perspective as highlighted by the recent PPWR regulation (link to another article), it should also steer clear of microplastic and PFAS contamination.

Qwarzo: its contribution to Circular Economy

Qwarzo is a solution provider for circular economy and food packaging. The company has developed the patented Qwarzo® technology, consisting of a silica-based mineral coating that applied to materials, such as paper, enhances their features, making them resistant to water, oil and other impacting agents, is fully PMP-free (Plastic, Microplastic, Pfas).

Qwarzo® technology is the sustainable innovation the market has been waiting for to address the ecological transition in packaging and food packaging.